Decarbonisation and Energy Transition

Your partner in Sustainability

Air Liquide is deeply committed to creating a positive impact on both the environment and society. Our strategy and actions are designed to address crucial challenges the world faces today, where we can make an impact and thus invent a sustainable future.

Ambient Air used to produce Oxygen, Nitrogen and Argon do not negatively impact the climate when used. The largest contributor to climate impact comes from energy needed to run our production process and transport of goods to customers. This makes it easier for us to design our Climate smart offers.

Low Carbon gases

Air Liquide continuously innovates to support its customers both industrial performance and reduction of environmental footprint. Many industries use gases such as Oxygen, Nitrogen, Argon and Carbon Dioxide (CO₂) in their manufacturing processes, which carry carbon footprint from the gas production and transportation. That is why Air Liquide has developed ECO ORIGIN™, a range of certified low-carbon gases produced with renewable energy sources to support customers’ decarbonisation efforts.

Clean Energy

As a pioneer in Hydrogen, Air Liquide is convinced that this molecule will be decisive in the energy transition towards the Hydrogen fuel economy. Hydrogen will be key to achieving this goal by making it possible to meet two major challenges to which Air Liquide is committed: decarbonising the heavy industry with clean energy and revolutionising mobility.

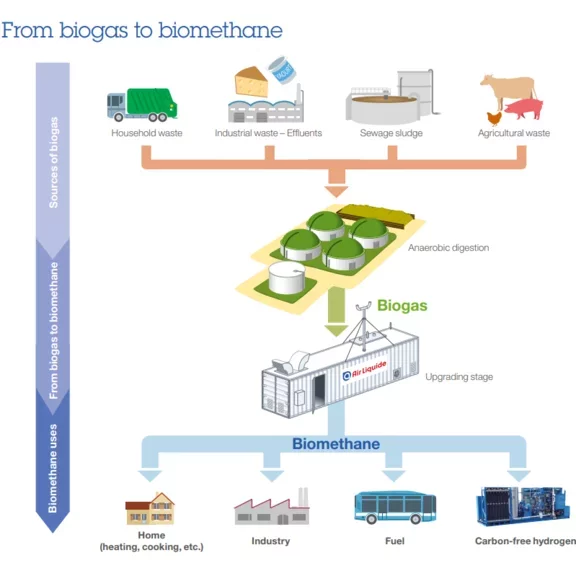

Waste to Energy

Our solutions for the entire supply chain include:

- "Upgrading" of biogas and purification of biomethane

- Liquefaction and distribution

- Biomethane refueling stations for vehicles.

In fact, Air Liquide works with several partners to convert organic resources into biogas, designs and implements purification technologies (Medal Membrane) to make biomethane.

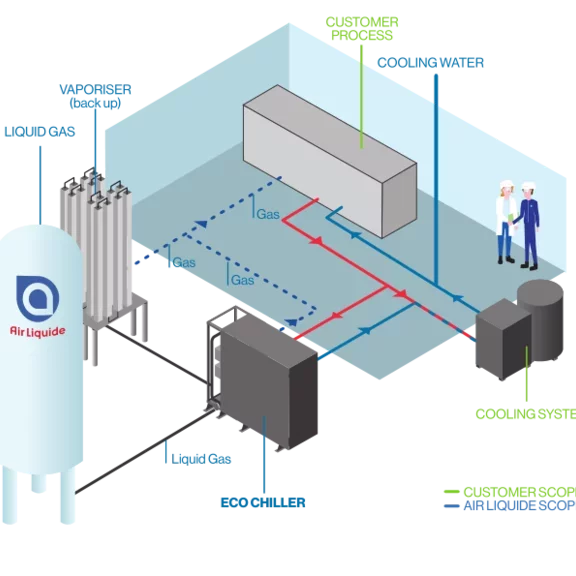

Cooling process efficiency

Air Liquide offers its customers a range of technologies tailored to their needs, enabling them to decarbonise their own operations. This includes specialised technology that helps to provide customers with energy cost savings while maintaining a constant temperature during process cooling.

Our offer for a more sustainable future

Related Gases

Industrial Gases

Premium Gases

Related Equipment

ECO CHILLER™ Heat Exchanger

Our automated heat exchanger equipment is designed to improve the efficiency of your cooling process. The system works by recycling the cold generated by the Liquid Nitrogen vaporisation, back into your cooling system and conveniently plugs into your watercooling network. The pre-cooled water thus relieves your cooling unit and reduces the energy costs of process cooling.

Why Choose Us

-

Industry Leader

We are a global leader in gases, technologies and services for Industry and Health. -

Reliability

Our solutions are reliable, reproducible and in compliance with stringent and ever-evolving regulations. -

Expertise

Leverage our global network of industry experts tailored to your unique challenges. -

One-Stop Solution Provider

Access a comprehensive suite of products, supply modes, and services designed for your specific requirements. -

Extensive Infrastructure Network

Benefit from our robust production and filling infrastructure, including extensive pipeline networks. -

Focus on Quality

Expect nothing less than the highest standards in process and product quality. -

Sustainability

Embrace our solutions that support your highest performance while minimising environmental impact.

Contact Us

Let our team get back to you on your specific enquiry.