The choice of lasing and assist gases plays a key factor in determining the reliability of the laser, the lifespan of the optics and output power. The LASAL™ gases are strictly controlled to minimise the content of impurities (moisture, hydrocarbons, etc.) to improve laser power and overall performance.

Air Liquide has defined laser gases for each type of laser source according the manufacturers' specifications to achieve the desired surface.

Our Complete Laser Offer

Ready to support your business

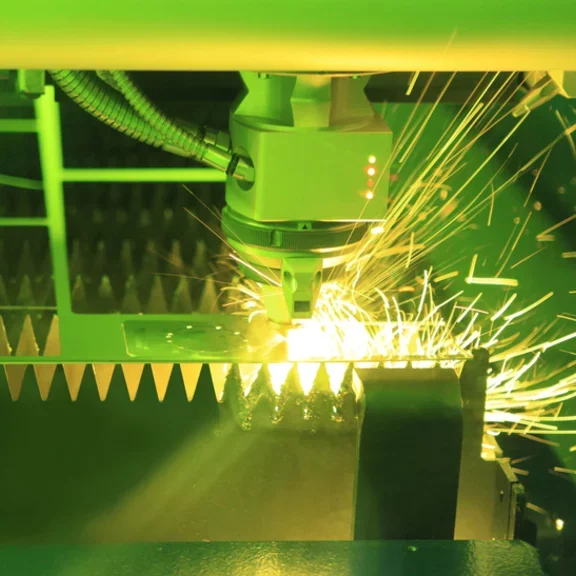

LASAL™ Lasing Gases

Our LASAL™ brand for CO₂ lasers comprise of Air Liquide's trademarked unique blend of at least three components: Carbon Dioxide (CO₂), Nitrogen (N₂) and Helium (He). Depending on the laser source used, they are available either as separate gases or pre-mixed.

Let our team find you the right lasing gas based on your laser manufacturer's recommendation.

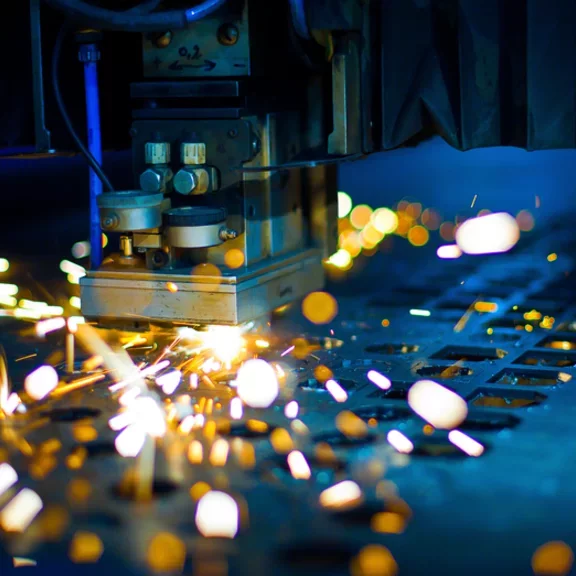

LASAL™ Assist Gases

Our assist and process gas range supports the quality and speed of your laser cutting. Available in high pressure, high flow Nitrogen packs to meet ever more demanding applications, and as high purity Oxygen to enable faster, cleaner cuts.

LASAL™ 2001

Clean Cuts| Gases |

Common Materials |

| Nitrogen |

Stainless Steel and Aluminium |

LASAL™ 2003

Cutting Speed| Gases |

Common Materials |

| Oxygen |

Carbon Steel and other metals depending on its thickness |

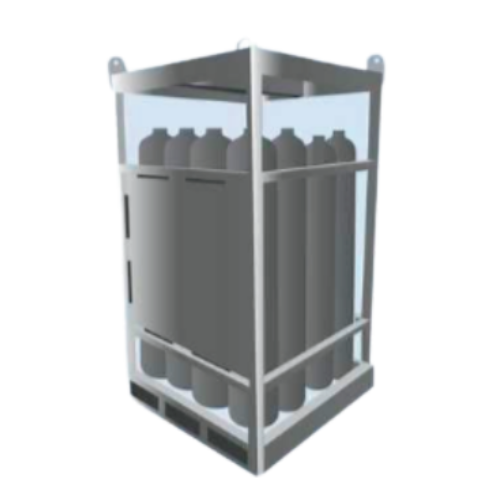

Product Packaging Options

To suit the demands of your business

| Packaging Types |

Cylinder |

Pallet |

Microbulk |

Bulk |

|---|---|---|---|---|

| Monthly Consumption Rate To be used for reference only |

up to 500 Nm³ | up to 1,000 Nm³ | up to 5,000 Nm³ | up to 500, 000 Nm³ |

Get Answers

Our team is ready to recommend you a best fit set up