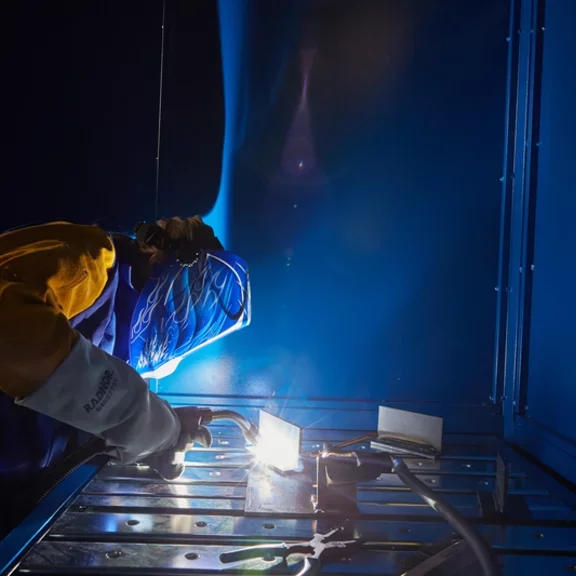

ARCAL™ Welding Gas

Simply the right choice of shielding gas solutions

ARCAL™, Air Liquide's premium brand gas solutions for practically any welding needs, offers four ready-to-weld argon mixtures designed to be reliable, simple, and high-performing.

If you are looking for the best MIG, MAG or TIG welding gas, our ARCAL™ gas range is specifically formulated to produce low oxidation, spatter, and fumes for stainless steel and other materials. Its excellent arc striking and wetting properties give a smooth bead profile, making it ideal for pulsed welding.The entire range complies with American Welding Society (AWS) and ISO 14175 welding standards.

Our Complete Welding Offer

Ready to support your business

ARCAL™ - Our Range of Welding Gases

Simply high performance - 4 essential Argon mixtures covering all applications

Simply high performance

4 essential Argon mixture covering all applications

ARCAL™ Prime

For high weld qualityThis high-purity offer is ideal for a wide range of welding applications, including TIG and plasma welding of various materials like titanium, as well as MIG welding of copper alloys and aluminum. It's an excellent root shielding solution for all kinds of welding.

With 99.998% argon, ARCAL™ Prime is a pure gas solution that delivers dependable weld bead integrity and weld soundness, making it the perfect choice for your arc welding needs.

| Process | Material |

|---|---|

| GMAW | Commonly used in Aluminum, Stainless steel |

| GTAW / PAW | Stainless steel, Aluminium, Titanium, nickel and Copper Alloys |

ARCAL™ Chrome

For weld quality of all gradesIt is a versatile blend that works well with all stainless steel welding including manual, automatic, and robotic welding.

Its carefully selected CO₂ content ensures good wetting and corrosion resistance. It reduces filler material consumption and post-welding operations, thanks to its low spatter emissions.

| Composition | Process | Material |

|---|---|---|

| Ar - CO₂ mix | GMAW | Stainless Steels |

ARCAL™ Speed

For high productivityWhen time is a critical factor and quality cannot be compromised, this gas blend is the perfect choice for arc welding. ARCAL™ Speed is expertly designed for high-travel speed and high-deposition rate MAG welding of carbon steels.

It is highly adaptable, produces low fume and spatter emissions, and reduces post-welding operations. It has a spatter-free pulsed mode with clean metal transfer. Perfect for X-ray quality welding, and other demanding applications.

| Composition | Process | Material |

|---|---|---|

| Ar - CO₂ mix | GMAW |

Carbon Steels (Non and Low Alloyed) |

ARCAL™ Force

For high toleranceThis blend is a powerful MAG welding solution for heavy carbon steel structures. It tolerates all surface contamination and gaps, is engineered for heavy use, and suits solid and flux cored wire.

Ideal for earthmoving, agriculture, bridge building, and ship modules welding applications.

ARCAL™ Force is the perfect choice for your toughest and most challenging welding applications.

| Composition | Process | Material |

|---|---|---|

| Ar - CO₂ mix | GMAW |

Carbon Steels (Non and Low Alloyed) |

Product Packaging Options

To suit the demands of your business

| Packaging Types |

Cylinder |

Pallet |

Microbulk |

Bulk |

|---|---|---|---|---|

| Monthly Consumption Rate To be used for reference only |

up to 500 Nm³ | up to 1,000 Nm³ | up to 5,000 Nm³ | up to 500, 000 Nm³ |

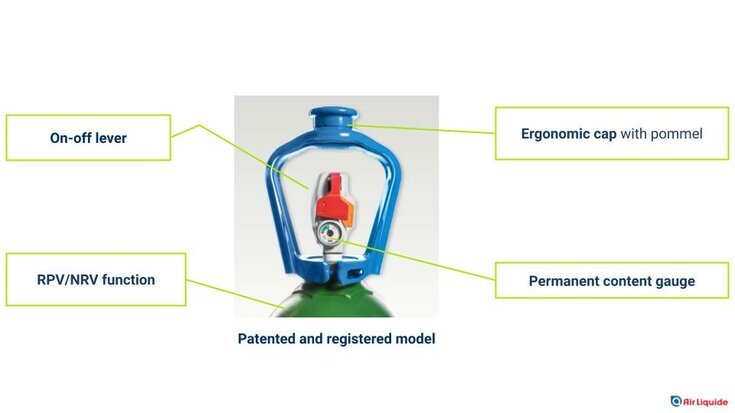

Premium Cylinder TOPs

Focusing on simplicity and safety

Our Patented SMARTOP™ Cylinder Cap

A smart residual pressure valve with on/off lever and a permanent content gauge

- Smooth and safe opening and immediate gas cut-off

- Ergonomic cap with pommel for easy handling

- Gas content monitoring at a glance

- Prevents back-flow contamination

Unlocking the Hidden Costs of Welding (UHCW)

Find the hidden costs robbing your profits

Get Answers

Our team is ready to recommend you a best fit set up