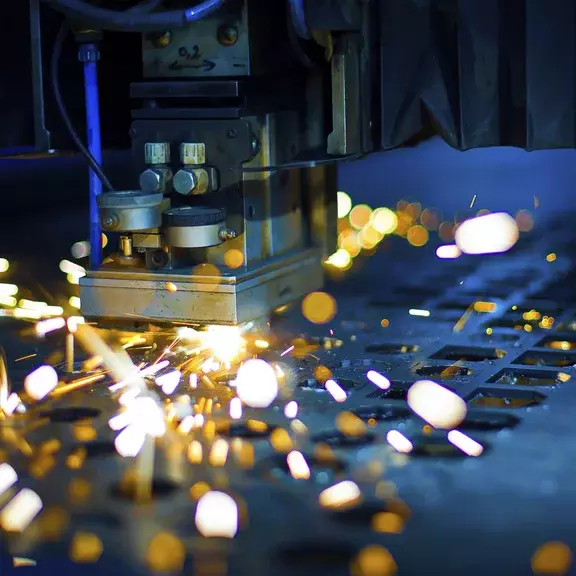

Cutting and Welding

Our solutions for flame, plasma and laser cutting

The right gas for each particular situation

Welding and cutting are industrial fabrication processes used to transform raw materials - plate metal, tube stock, etc. - into machines and structures.

Cutting is used to separate pieces of metal sheets, structures and pipes. This is achieved by using flame, plasma or laser cutting where the gas is an active component to melt, burn, vaporise or blow away excess material, thereby creating clean cut edges.

Welding joins workpieces, usually metals, by melting their edges so that they fuse together. The main process is arc welding. For this process, a gas is required to shield the liquid pool from the ambient air. Argon-based mixtures are the main industry shielding gases.

Our primary offer is based on three leading gas ranges:

- ARCAL™ for arc welding (TIG / MIG or MAG processes)

- FLAMAL™for oxy-fuel cutting and for flame heating or braze-welding (oxyacetylene welding)

- LASAL™ for laser cutting and welding