Sintering (N2+H2+H2O, N2+H2+CH4)

Why do sintering with Air Liquide solutions?

Why do sintering with Air Liquide solutions?

A gas atmosphere suitable for sintering

Air Liquide offers gas solutions designed specifically for your needs:

nitrogen-hydrogen mixtures at different percentages (N 2 +H 2 <10%) to obtain a weakly reactive neutral atmosphere

Atmospheres of endothermic gas diluted with nitrogen

Tailor-made solutions

Our experts and our solutions for gas distribution, mixers and dilute endothermic atmosphere generators offer you:

Great flexibility in the composition of the atmosphere to adapt to your need

Optimal productivity: our experts offer you specific solutions for the materials to be treated to increase your productivity

Process control: audit and analysis to optimize the composition of the atmosphere and the working parameters (pressure and flow) at each stage of production

Managing security responsibly

Our experts, thanks to a solid experience in the field of powder metallurgy and heat treatments, are at your side for:

- Accompany you in the implementation of gases in complete safety.

- Train you on safety and the safe use of our gases.

The Air Liquide offer

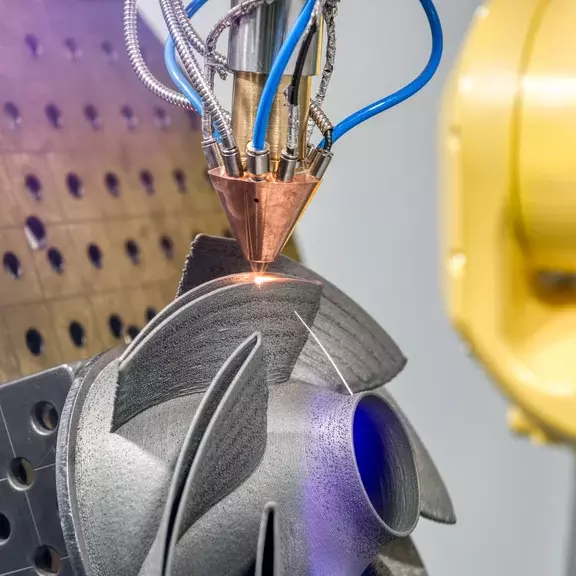

Air Liquide supports you in your metal powder sintering processes and offers you suitable solutions for high temperature treatment.

Quality gases and equipment for optimum sintering

Thanks to their low levels of humidity and impurities, Air Liquide gases contribute to improving the performance of sintering technologies. Depending on your quality requirements for sintered parts, we offer nitrogen and hydrogen mixtures or dilute endothermic gas atmospheres.

For sintering, Air Liquide offers functional equipment for implementing gases:

- Distribution systems, gas mixers, ...

- Combustible gas safety management

All our installations are designed in compliance with standards such as NF EN 746-3 (implementation of gases in thermal treatment installations).

The different atmospheres in sintering

Our experts advise you on the gases at each stage of manufacture.

After sintering, the final part can also undergo a finishing treatment. Air Liquide also offers you innovative gas solutions also for the post sintering operation: cryogenic machining to improve dimensional precision or surface heat treatment to increase the resistance of the first surface layer.